PTFE Insulated High Voltage Corona Resistant

Price 400 INR/ Meter

PTFE Insulated High Voltage Corona Resistant Specification

- Connector Type

- Bare Wire or Custom Terminals

- Conductor Type

- Stranded or Solid

- Temperature

- -65C to +260C Celsius (oC)

- No Of Core

- Single Core

- Product Type

- PTFE WIRE

- Material

- Polytetrafluoroethylene (PTFE)

- Function

- High Voltage Insulation, Corona Resistance

- Usage

- Electrical Wiring in High Voltage Applications

- Voltage Surge

- Up to 25 KV

- Frequency (MHz)

- DC to 1000 MHz Megahertz (MHZ)

- Cable Capacity

- Insulation Material

- PTFE

- Conductor Material

- Silver Plated / Nickel Plated Copper

- Length

- Standard or Custom (e.g., 100 m, 500 m) Meter (m)

- Size

- Various (e.g., 0.5 mm - 10 mm)

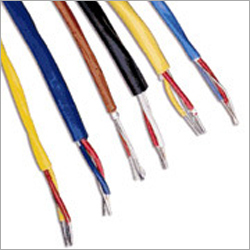

- Color

- Red, Blue, Black, White, Yellow, Green, etc.

- Diameter

- 1.0 mm - 10.0 mm Millimeter (mm)

- Application

- Radar, Aerospace, Power Electronics, X-ray Equipment

PTFE Insulated High Voltage Corona Resistant Trade Information

- Minimum Order Quantity

- 100 Meters

- FOB Port

- Ghaziabad

- Supply Ability

- 1000 Meters Per Day

- Delivery Time

- 15 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Customized

- Main Domestic Market

- All India

- Certifications

- ISO Certified

About PTFE Insulated High Voltage Corona Resistant

We are manufacturing PTFE high voltage cables . capable of operating upto 22 kv rms-50 kv DC working. This cable is made up of silver plated copper wire,nickle Plated copper wire wrapped by CR ptfe tape/foil than fused by heating. Size of conductor awg 28 to awg 10. Insulation thickness ranging from 0.5 mm upto 2.5 mm.

Outstanding Electrical Performance and Safety

Designed for high voltage insulation, this PTFE wire can sustain voltages up to 25 KV and a wide frequency range (DC to 1000 MHz). The insulation provides excellent corona resistance and superior dielectric strength, which enhances worker and equipment safety by minimizing the risk of electrical breakdown, even in challenging environments.

Durability in Extreme Conditions

Engineered to perform in temperatures ranging from -65C to +260C, the wire resists most acids, oils, and solvents, making it exceptionally suitable for harsh industrial or aerospace settings. High tensile strength and elongation at break ensure consistent flexibility and durability over time, even in applications subject to vibration or movement.

Flexible Customization and Easy Installation

Our PTFE High Voltage Wire is available in stranded or solid conductors, various sizes (0.5 mm10 mm), and multiple colors. Packaged as coil, spool, or drum, with options for bare or custom terminals, it can be tailored to fit diverse installation needs, enhancing usability across different sectors.

FAQs of PTFE Insulated High Voltage Corona Resistant:

Q: How does PTFE insulation improve high voltage cable performance?

A: PTFE insulation provides superior dielectric strength ( 25 kV/mm), remarkable flame retardancy, and corrosion resistance. These properties protect the conductor from electrical breakdown, high temperatures, and harsh chemicals, making the cable exceptionally reliable in high voltage and critical environments.Q: What industries benefit most from using this high voltage PTFE wire?

A: Industries such as aerospace, radar, power electronics, and medical imaging (X-ray equipment) require high voltage wiring with outstanding electrical and chemical resistance. The PTFE wire meets these demands by offering excellent insulation performance, safety, and longevity.Q: When is it advisable to choose a corona resistant cable?

A: Corona resistant cables are essential when operating at high voltages (1025 KV) or in high frequency (up to 1000 MHz) applications, where electrical discharge (corona) can degrade insulation. Using PTFE insulated cable in these scenarios ensures reliable, long-lasting operation and reduces maintenance costs.Q: Where can the PTFE insulated wire be installed, and what are its packaging options?

A: This wire is suitable for indoor and outdoor installations, including harsh industrial or laboratory environments. It is supplied in coils, spools, or drums, and can be custom ordered in lengths to suit specific project requirements.Q: What is the process of ordering and customizing this cable?

A: Clients can specify required length, diameter (110 mm), conductor material (silver/nickel plated copper), core size, color, and connector type. Manufacturers in India can accommodate standard (e.g., 100 m, 500 m) or custom orders, ensuring the cable matches the technical and logistical needs of each application.Q: How should this cable be used for optimal benefit?

A: To maximize performance, use the cable within its rated voltage (1025 KV), temperature range (-65C to +260C), and avoid physical damage during installation. Its flexibility and select mechanical properties ensure it fits complex routing while delivering reliable, long-term insulation.Q: What are the key benefits of choosing PTFE insulated, high voltage, corona resistant wiring?

A: The main advantages include high dielectric strength, outstanding flame and chemical resistance, flexibility over a wide temperature range, RoHS compliance, and compatibility with several applications, ensuring operator and equipment safety while reducing downtime and replacement frequencies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PTFE WIRES & CABLE Category

Flat Bonded Ribbon Cable

Price 400 INR / Meter

Minimum Order Quantity : 100 Meters

Product Type : PTFE WIRE

Color : Grey or Multicolor (as per standard)

Material : Polyvinyl Chloride (PVC)

Function : Signal Transmission

PTFE Hook-Up Wires

Price 124 INR / Mile

Minimum Order Quantity : 500 Meters

Product Type : HookUp Wire

Color : [Red Blue White]

Material : Copper with PTFE insulation

Function : Electrical connection and signal transmission

Multicore Shielded Jackted Cables and Wires

Price 60 INR / Meter

Minimum Order Quantity : 100000 Meters

Product Type : Multicore Cables

Color : Black Green Orange

Material : Copper with PVC insulation

Function : Power transmission

PTFE Wire

Product Type : PTFE Wire

Color : Blue Yellow Brown Black

Material : PTFE Insulated Copper

Function : Power Transmission

Send Inquiry

Send Inquiry